Tuesday, December 30, 2025

Integrated Process Excellence (IPE): The Deployment Framework for Forrester Adaptive Process Orchestration (APO)

Integrated Process Excellence (IPE):

The Deployment Framework for

Adaptive Process Orchestration (APO)

Enabling Enterprise-Scale

Autonomous Operations Through AI-Augmented Process Excellence

Adaptive

Process Orchestration tells the industry WHERE it must go.

Integrated

Process Excellence provides the method to GET THERE.

Executive Summary

Enterprises across every industry

are accelerating toward autonomous operations, seeking productivity, agility,

and resilience unlocked by AI agents, nondeterministic decision-making, and

adaptive workflows. Forrester’s introduction of Adaptive Process Orchestration

(APO) defines a new automation category that unifies AI agents, generative

reasoning, traditional workflow engines, and enterprise integration into a

single orchestration capability.

However, APO - like earlier shifts

from BPM (Business Process Management) to DPA (Digital Process Automation),

from Robotic Process Automation (RPA) to Intelligent Automation - lacks a

structured, enterprise-ready deployment methodology. Vendors define APO

capabilities, but enterprises lack the HOW-TO framework required to

operationalize these capabilities across people, process, data, and governance.

Integrated Process Excellence

(IPE) fills this strategic gap.

IPE is a six-step,

enterprise-scale operating model that provides the process, data, governance,

organizational, and change-management blueprint required to deploy APO

successfully. While APO defines what next-generation orchestration

should look like, IPE defines how to implement it, measure it, and scale

it.

This white paper details how IPE

operationalizes APO, enabling organizations to move from deterministic

workflows to hybrid AI-enabled, agentic, adaptive operations.

1. The Need for Adaptive

Process Orchestration (APO)

Forrester defines Adaptive Process

Orchestration as:

“An

automation platform that uses AI agents and nondeterministic control flows, in

addition to traditional deterministic control flows, to meet business goals,

perform complex tasks, and make autonomous decisions.”

- Forrester Research, 2025

Traditional workflow engines (BPM,

DPA), RPA bots, and deterministic control systems cannot adapt fast enough to

dynamic business environments. APO fills this capability gap by blending:

- AI agents capable of complex reasoning

- Nondeterministic decision paths

- Traditional deterministic workflows

- Automation fabric integration

- Long-running, cross-domain process orchestration

APO provides the technology

foundation for autonomous operations. What APO does not provide is the How-To deployment

framework to implement this vision at enterprise scale. Enterprises need:

- A process framework

- A governance model

- A data strategy

- A change-management methodology

- A way to identify where AI agents belong in workflows

- A system for training, controlling, and measuring AI

agents

- A repeatable playbook for APO adoption

These needs are outside the scope

of APO platforms, but they are precisely what IPE was designed to deliver.

2. Integrated Process

Excellence (IPE): The Missing HOW-TO for APO

IPE is a proven six-step

methodology enabling organizations to create, document, communicate, measure,

and continuously improve enterprise processes with embedded AI, automation, and

advanced analytics.

IPE Six-Step Model

- Create a Positive Environment – Governance, roles,

change readiness

- Define the Process – Scope, SIPOC, workflows,

constraints

- Document the Process – Detailed tasks, orchestration

diagrams, data flows

- Communicate the Process – Training, adoption,

stakeholder alignment

- Measure & Control – KPIs, dashboards, agent

performance metrics

- Continuous Improvement – Long-term model tuning,

drift control, optimization

These six steps map directly onto

the requirements Forrester identifies for enterprises deploying APO.

3. Mapping APO Requirements to

IPE Deployment Capabilities

Forrester highlights five

capabilities required for Adaptive Process Orchestration.

IPE provides the method to operationalize each one.

APO Capability #1: Model Option

& Constraint Management

This includes business rules,

guardrails, regulatory constraints, role-based action limits, and AI behavioral

boundaries.

IPE Deployment Layer

- IPE Step 1: Governance structures, roles, decision

rights

- IPE Step 2: Documented process constraints

- IPE Data Fabric: Policy-driven data access and

control

- IPE Compliance Integration: Risk, escalation paths,

auditability

Outcome:

AI agents operate safely within organizational, regulatory, and mission

constraints.

APO Capability #2: Content

& Format Processing

APO requires the ability to

process PDFs, emails, images, logs, transcripts, and structured/unstructured

knowledge.

IPE Deployment Layer

- IPE Document Analysis Framework

- IPE-Chuck/Embed Architecture

- RAG Configuration Schema

- Semantic search and contextual retrieval integration

Outcome:

APO receives clean, structured inputs for accurate reasoning and task

execution.

APO Capability #3: Ability to

Create AI Agents

Organizations must define agent

roles, skills, reasoning modes, environment awareness, KPIs, escalation

behaviors, and integration points.

IPE Deployment Layer

- Persona-based agents (CFO, COO, Plant Manager,

Quality Director, etc.)

- Cause-and-effect reasoning tables

- Enterprise AI agent definition templates

- Step 5: Agent performance metrics and thresholds

Outcome:

AI agents have clear operational purpose, defined reasoning modes, and

measurable outcomes.

APO Capability #4: Agentic

Orchestration

APO combines deterministic

workflows with flexible, AI-driven decision paths.

IPE Deployment Layer

- SIPOC → Activity → Task → AI-Insertion Points

- Hybrid orchestration maps showing rules + AI decision

nodes

- Data fabric ensuring all agents use consistent

enterprise intelligence

- Operational readiness workflows

Outcome:

Organizations achieve scalable, governed AI-driven workflows with real-time

adaptability.

APO Capability #5: Governance,

Data, and IP Protection

APO requires secure handling of

data, protection of intellectual property, and auditable oversight of AI agent

behavior.

IPE Deployment Layer

- Enterprise Data Structure Analysis

- Security and domain access control

- Step 4: Transparent communication of governance and

policies

- Step 6: Drift detection, retraining loops, and

continuous improvement

Outcome:

Enterprises maintain compliance, control, and trust across APO deployments.

4. APO Is Technology. IPE Is

the Enterprise Operating Model.

APO platforms unify automation

technologies.

IPE unifies the organization

around how to deploy them.

|

Need |

APO Explains |

IPE Provides |

|

AI agents |

Yes |

Operational definitions, training,

governance |

|

Nondeterministic flows |

Yes |

Identification, documentation,

readiness assessments |

|

Orchestration |

Yes |

Process design and persona

workflows |

|

Data integration |

Yes |

Enterprise data fabric schema |

|

Governance |

Partial |

Complete governance operating model |

|

Deployment method |

No |

YES – full 6-step framework |

|

KPI system |

No |

Comprehensive measurement &

control |

|

Cultural adoption |

No |

Change-management and communication

plan |

5. APO + IPE Enables Autonomous

Operations

The combination of APO platforms

and IPE methodology allows organizations to implement:

- Autonomous workflows that dynamically adjust in

real-time

- AI agents operating within documented constraints

- Predictive and generative orchestration across

business functions

- Seamless integration between humans, rules engines,

and AI models

- Continuous improvement loops using agent telemetry

and process performance metrics

APO provides the capability.

IPE provides the discipline and repeatability.

Together, they unlock autonomous

operations at enterprise scale.

6. Deployment Roadmap: APO

Implementation Using IPE

A typical APO deployment using IPE

unfolds in three waves:

Wave 1: Foundation (Weeks 1–8)

- Governance & role definition

- Data fabric and knowledge model structure

- Process identification (APE-ready workflows)

- AI agent definition templates

- Measurement frameworks

Wave 2: Orchestration &

Enablement (Months 3–6)

- Hybrid orchestration maps (deterministic + AI nodes)

- APO platform configuration

- RAG + embedding pipeline integration

- Pilot use cases (Plant Manager Mode, Quality Mode,

COO Mode)

- Model guardrails & compliance design

Wave 3: Scale & Autonomous

Operations (Months 6–18)

- Enterprise APO rollout

- Multi-persona agent networks

- Cross-domain orchestration (Quality ↔ Operations ↔

Finance ↔ Supply Chain)

- Drift analysis & continuous optimization

- Expansion to new processes, business units, and

partners

The outcome:

A governed, transparent, AI-driven operational system capable of autonomous

decision-making across complex enterprise environments.

7. Why APO Needs IPE To Succeed

Without IPE, APO becomes another

powerful technology category lacking a structured deployment method, just like

RPA in 2017 or BPM in the 2000s.

With IPE, APO becomes:

- Deployable

- Understandable

- Governable

- Measurable

- Scalable

- Culturally adoptable

IPE provides the organizational

and architectural backbone enabling APO’s full potential.

8. Conclusion: IPE Is the

Essential HOW-TO Framework for APO

Forrester’s introduction of

Adaptive Process Orchestration marks the beginning of a new automation era. APO

combines AI agents, nondeterministic flows, deterministic workflows, and

automation fabric integration to move enterprises toward autonomous operations.

APO

is technology strategy.

What

enterprises need is a deployment framework.

IPE is that deployment framework. IPE

provides:

- The governance model

- The deployment roadmap

- The data architecture

- The agent definition system

- The measurement framework

- The cultural adoption approach

- The documentation and communication infrastructure

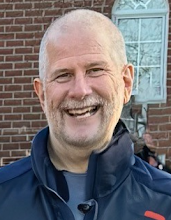

John

M. Cachat is a serial visionary with deep expertise in building enterprise

process infrastructure, delivery governance frameworks, and cross-functional

execution systems using AI LLMs. Creator of the Integrated Process Excellence

(IPE) model, aligning strategy, process, governance, KPIs, and performance

across organizations. Proven record leading multi-site technology deployments,

strengthening operational discipline, building transparency through dashboards

and reporting, and driving accountable execution cultures. Experienced managing

complex portfolios, customer and supplier relationships, and cross-functional

initiatives that improve reliability, predictability, and business impact.

IPE

Services provides Integrated Process Excellence consulting, workshops, and

deployment support

Contact - johncachat@ipe.services

Want

to Learn More? - Available on Amazon - https://www.amazon.com/dp/B0G4NC4KML

Friday, December 26, 2025

FREE Document - Quality Cost Research and How To Resources

FREE Document - Quality Cost Research and How To Resources - This document is designed to help organizations leverage both ASQ Internet of Everything (IoE) Cost of Quality Report technical research and the how-to guidance resources provided in Quality Cost From Theory to Deployment with AI LLMs book to effectively for maximum impact on quality cost management and organizational performance.

https://drive.google.com/file/d/1kimr4QKfkI856V0jS84GUeesIGV0Z51V/

Thursday, December 11, 2025

Not sure what to do with your AI efforts at your company?

Not sure what to do with your AI efforts at your company?

Without the Integrated Process Excellence (IPE) infrastructure, an AI LLM is merely a smart generalist and falls short of being a process expert necessary for effective business transformation. To achieve operational excellence and drive continuous improvement, the integration of such infrastructure is critical, especially in the context of digital transformation, as highlighted by experts like John Cachat.

Without the Integrated Process Excellence (IPE) infrastructure, AI LLMs and Agents are just a smart generalist. They can only produce generic thoughts about excellence - it cannot support with Operational Excellence, Business Transformation, or Continuous Improvement efforts with rapid path to actionable insights. IPE provides AI LLM context needed to execute and measure results.

The complete series of Integrated Process Excellence for the

AI Era is now available on Amazon https://www.amazon.com/dp/B0G4NC4KML

Any money left in the 2025 training budget? – these books

provide a great framework for next year training efforts.

NEW BOOK - Quality Cost From Theory to Deployment with AI LLMs - Leveraging the IPE Process Platform

NEW BOOK - Quality Cost From Theory to Deployment with AI LLMs - Leveraging the IPE Process Platform

Operations

executives seeking competitive advantage through operational excellence,

business transformation, and continuous improvement efforts. Quality seeking to

eliminate frustration with compliance systems that don't drive improvement.

Plant Managers struggling to prioritize among competing problems. CFOs

demanding ROI justification for quality investments. IT leaders implementing

AI/LLM solutions that need domain expertise. Engineers designing products for

manufacturability. Anyone responsible for eliminating waste and improving

profitability.

Available

on Amazon: https://www.amazon.com/dp/B0G5X9K9NG

Happy to have a call if you would

like to learn more.

https://www.linkedin.com/in/johncachat/

This comprehensive guide reveals

how to implement a Quality Cost Accumulator - an AI-powered system that

integrates data from ERP, MES, QMS, PLM, and unstructured data. You'll discover

how Large Language Models (LLMs) trained on your Integrated Process Excellence

(IPE) Process Platform can automatically categorize costs, identify failure

patterns, predict risks, and generate persona-specific insights for every

stakeholder from operators to executives.

What You'll Learn:

Multi-Persona Intelligence - How to configure systems that automatically generate tailored insights for CFO (EBITDA impact), COO (throughput constraints), Plant Manager (immediate actions), Engineering (design failures), Purchasing (supplier quality), Sales (customer risk), Marketing (brand exposure), and HR (training gaps)

The Super Cube Approach - How to integrate unstructured data (emails, complaints, technician notes) with structured data (production logs, inspection results, financial transactions) to reveal complete cause-and-effect chains

#QualityCost

#OperationalExcellence #ManufacturingAI #ProcessImprovement #LeanManufacturing

Thursday, December 4, 2025

we are all human diversity books

If you know anyone trying to explain to kids about differences in people and inclusion, prejudice / racism - you might find these “we're all human” diversity book helpful – available on Kindle

I am Human - A Bird Story - https://www.amazon.com/dp/B0G53L5BCC

I am Human - A Dog Story - https://www.amazon.com/dp/B0G53J5R41

I am Human - A Horse Story - https://www.amazon.com/dp/B0G53JVJWX

I am Human - A Cat Story - https://www.amazon.com/dp/B0G53CTQ5Y

I am Human - A Snake Story - https://www.amazon.com/dp/B0G454K2F5

I am Human - The Complete Series - https://www.amazon.com/dp/B0G3XTRWL8

"All Different, All the

Same"

Join a delightful journey through

the animal kingdom where young readers discover an amazing truth: creatures who

look very different can actually be the same kind of animal!

Meet spotted Dalmatians and fluffy

golden retrievers—both dogs! Marvel at tabby cats with stripes and sleek black

cats with no patterns—all cats! Explore how horses come in every color from

white to black, with spots and patches in between. Discover parrots wearing

bright red, blue, green, and yellow feathers—yet all are parrots.

Through vibrant illustrations and simple, engaging text, children learn that just like dogs can have long fur or short fur, big ears or small ears, people come in all different colors, sizes, and features too. We have different hair textures, eye colors, skin tones, and body types—but we're all humans, all part of the same family.

Purpose:

This book introduces young

children (ages 3-7) to the biological concept that members of the same species

can look remarkably different from one another. By starting with familiar

animals, it helps children understand genetic diversity in a concrete, visual

way before applying this concept to human diversity.

The gentle comparison encourages

children to:

- Celebrate differences rather than fear them

- Understand that external appearance doesn't change

what we fundamentally are

- Develop empathy and inclusivity from an early age

- See diversity as natural, normal, and beautiful

It's a story about belonging,

acceptance, and the wonderful variety found in nature—including in ourselves.

#prejudice

#racism

#inclusion

#diversity

Wednesday, December 3, 2025

Not sure what to do with your AI efforts?

Not sure what to do with your AI efforts? The complete series of Integrated Process Excellence

for the AI Era is now available on Amazon https://www.amazon.com/dp/B0G4NC4KML

Any money left in the 2025 training budget? – these books provide

a great framework for next year training efforts.

#operationalexcellence, #business transformation, #digitaltransformation,

#continuous improvement, #AILLM

Monday, October 20, 2025

The Future of Integrated Process Excellence (IPE)

The Future of Integrated Process Excellence (IPE)

Watch the video to learn more

https://www.linkedin.com/pulse/future-integrated-process-excellence-ipe-john-m-cachat-zpb0e

The future belongs to

organizations that can adapt faster than their environment changes.

Traditional management focused on

output metrics and dashboards—reporting what already happened. IPE’s next

evolution is real-time process management, where systems sense variation and

respond automatically. The role of leadership shifts from supervising people to

designing systems that learn and improve themselves. Success is no longer

determined by who works hardest, but by how well the system is built to sustain

performance.

2. AI and Intelligent

Automation in IPE

Artificial Intelligence extends

IPE’s principles of measurement, control, and improvement.

AI can analyze Key Variables

across the enterprise to reveal previously hidden cause-and-effect

relationships. Intelligent automation closes the loop—detecting process drift,

triggering actions, and verifying results without manual intervention. Predictive

analytics transforms prevention from an event to continuous, autonomous

behavior within the system. IPE provides the structure that allows AI to

deliver value—because intelligence without process discipline produces chaos,

not control.

3. Human Intelligence: The

Leadership Multiplier

Even as automation expands, people

remain the architects of purpose, ethics, and creativity. Leadership will focus

on sense-making—interpreting patterns, defining strategy, and shaping the

culture that AI cannot. The future leader is a system designer, not a task

controller. Emotional intelligence, communication, and learning agility become

the new differentiators of process excellence. IPE ensures that technology

amplifies human capability rather than replaces it.

4. Integration Across the

Digital Ecosystem

Future enterprises will operate

across ecosystems of suppliers, partners, and customers—each digitally

connected. IPE defines the common process language that links these entities

through shared data and performance metrics. Distributed data fabrics will make

process visibility global and instantaneous. Blockchain, IoT, and AI will

provide trust, traceability, and transparency required for integrated

excellence. Integration moves from internal alignment to inter-enterprise

orchestration—the next frontier of performance.

5. Continuous Learning and

Self-Improving Systems

The future IPE system is

dynamic—it learns, adapts, and improves continuously. Every process iteration

produces data that feeds back into the system for optimization. Lessons learned

are institutionalized in digital standards and process libraries. Feedback

cycles shorten from months to minutes, transforming the pace of improvement. IPE

evolves into an autonomous management framework, where improvement is no longer

driven by events but by design.

6. Sustainability as Strategic

Continuity

Sustainability will define

competitive advantage in the next decade. IPE positions organizations to

achieve economic, environmental, and social continuity by:

- · Embedding risk prevention into every process.

- · Optimizing resource efficiency through intelligent control.

- · Aligning corporate purpose with measurable process outcomes.

Sustainability in IPE is not a project—it is the natural result of a stable, self-correcting enterprise system.

Summary Insight The future

of IPE is intelligent integration—where every process is connected, every

decision is informed by data, and every improvement is built into the fabric of

work. Leadership will evolve from managing activities to managing systems of

intelligence. In this future, IPE becomes the digital nervous system of the

enterprise—sensing, learning, and acting in real time.

Managing Quality in the Modern Era with Integrated Process Excellence (IPE)

Managing Quality in the Modern Era with Integrated Process Excellence (IPE)

Quality in the modern enterprise is no longer a department or a compliance function—it is the outcome of an integrated management system. This chapter explains how Integrated Process Excellence (IPE) redefines quality as a property of every process, decision, and data stream across the organization. Quality is not inspected in or audited in—it is designed, defined, measured, and managed through cause-and-effect understanding.

Watch the video to learn more

Traditional quality programs

relied on end-of-line inspection and reaction to nonconformance.

In IPE, quality is achieved through process control, not after-the-fact

correction.

- Every process identifies its Key Input, Process,

and Output Variables (KIVs, KPVs, KOVs).

- Control systems detect variation early, allowing

teams to adjust before defects occur.

- Responsibility for quality is built into every

role—not limited to the Quality department.

Quality becomes an operational

discipline, not a policing function.

2. Defining Quality as

Conformance to Requirements

Quality is not subjective—it is

defined by meeting clearly understood and measurable requirements.

- Customer, regulatory, and business requirements are

translated into precise process definitions.

- Clarity replaces interpretation; variation replaces

opinion as the focus of management.

- Processes that are not defined cannot be

controlled—and uncontrolled processes cannot consistently meet

requirements.

IPE ensures that every process

begins with definition, not assumption.

3. Integrating Digital Systems

and Quality Data

Modern quality management depends

on data integration across systems—ERP, PLM, MES, CRM, and QMS.

- Design data (PLM) defines what should happen.

- Execution data (MES/ERP) shows what did

happen.

- Customer and field data (CRM) reveal what was

experienced.

By integrating these systems, IPE establishes digital traceability, making it possible to understand cause and effect across the full lifecycle—from design through customer use.

This integration transforms

“quality records” into real-time quality intelligence.

4. Quality 4.0: From Data

Collection to Intelligent Control

Artificial Intelligence (AI),

automation, and analytics extend the reach of quality management.

- Machine learning models can predict process drift and

trigger corrective actions.

- Automated inspection and sensor data enable

self-learning, self-adjusting systems.

- Digital twins simulate process outcomes before

changes are implemented.

IPE provides the structure that

allows these technologies to work—because AI cannot improve what is not

defined or measured.

5. Culture of Prevention and

Learning

Managing quality in the modern era

means building a culture where everyone prevents problems rather than reacts

to them.

- Root cause analysis evolves into success planning—defining

what must go right to achieve desired results.

- Lessons learned are built into process standards and

training.

- Leadership recognizes and reinforces behaviors that

build process capability, not just firefighting skill.

Quality becomes a shared mindset—we

don’t fix problems, we eliminate their causes.

6. Leadership’s Role in Modern

Quality

Leaders are accountable for

creating the system that produces quality.

- They ensure every process has definition,

measurement, and control.

- They use data for decision-making, not anecdotes or

assumptions.

- They align strategy, technology, and people around

the same integrated process framework.

In IPE, leadership behavior itself

becomes a quality variable—one that determines consistency and trust

across the enterprise.

Summary Insight

Managing Quality in the Modern

Era means managing processes intelligently.

IPE turns quality from a compliance cost into a strategic capability—where

cause and effect are visible, variation is controlled, and improvement is

continuous.

In this model, quality is not a department—it is the DNA of the enterprise.

Integrated Process Excellence (IPE) Across the Enterprise

Integrated Process Excellence

(IPE) Across the Enterprise

Integrated Process Excellence

(IPE) turns isolated departments and digital systems into a unified,

cause-and-effect enterprise. This chapter explains how integration—of data,

decisions, and people—creates visibility, speed, and alignment from the

boardroom to the shop floor. IPE’s

purpose is simple: connect everything that creates value so the organization

can manage as one system.

1. From Functional Management

to End-to-End Thinking

Most organizations still operate

in silos: Sales forecasts drive plans that Finance doesn’t trust, while

Operations react to late Engineering changes.

IPE replaces this fragmented approach with end-to-end process management,

linking activities from customer need → design → source → make → deliver →

support.

- Each process has clear ownership, inputs, outputs,

and metrics that connect to enterprise goals.

- Instead of optimizing functions, IPE optimizes flow—how

value moves across the enterprise.

- The focus shifts from firefighting within departments

to managing shared outcomes.

2. Data as the Integrator

True integration requires a

common language of data.

- IPE defines Key Variables (KIVs, KPVs, KOVs)

consistently across systems—ERP, PLM, MES, CRM, HRMS—so performance

relationships are visible.

- Data fabrics and integration hubs eliminate silos by

linking cause-and-effect across processes.

- Once data is standardized, analytics and AI can

detect patterns, predict risks, and drive improvement autonomously.

Data integration is not about

collecting more data—it’s about connecting the right data to the right

process decisions.

3. Digital Systems Aligned to

Process Logic

Most enterprise systems were built

around transactions, not processes.

IPE re-maps those systems to follow process flow rather than departmental

structure:

- ERP manages what is planned and delivered.

- PLM controls what is designed and changed.

- MES monitors what is produced and verified.

- CRM captures what customers need and

experience.

Through integration, these systems collectively form a digital twin of the business, enabling real-time visibility and control.

4. Integrating People and Roles

Technology alone cannot integrate

an enterprise—people do.

- IPE clarifies roles, responsibilities, and

interfaces so collaboration replaces escalation.

- Cross-functional teams own processes instead of

tasks, reinforcing shared accountability.

- Communication and recognition systems are designed to

reward process contribution, not just departmental results.

Integration builds trust: everyone

understands how their work affects the next step in the value chain.

5. Leadership and Governance of

Integration

Leaders sustain integration by

governing through processes, not hierarchies.

- Executive dashboards display process performance, not

just financial results.

- Governance reviews follow end-to-end processes

(Order-to-Cash, New Product Introduction, etc.) to resolve systemic

issues.

- Leadership accountability shifts from demanding

results to maintaining the systems that produce results.

Integration thus becomes the

framework for strategic alignment—strategy deployment, resource allocation, and

improvement all flow through the same process structure.

6. The Payoff of an Integrated

Enterprise

An integrated enterprise achieves:

- Transparency: Cause and effect are visible

across all levels.

- Agility: Rapid, coordinated response to

change.

- Efficiency: Elimination of redundancy, rework,

and hidden waste.

- Engagement: Everyone works within one system

of truth and purpose.

Integration turns data into

insight, insight into action, and action into sustained excellence.

Summary Insight

Integration is the heart of IPE.

When processes, data, systems, and people operate through one connected

framework, the organization stops managing parts and starts managing the whole.

That is the essence of Integrated Process Excellence—one company, one

system, one truth.

Integrated Process Excellence (IPE) Risk Resilience and Sustainability

Integrated Process Excellence (IPE) Risk Resilience and Sustainability

Watch the video to learnmore

https://www.linkedin.com/pulse/integrated-process-excellence-ipe-risk-resilience-john-m-cachat-nayge

1. From Reactive Risk

Management to Predictive Control

Traditional risk systems rely on

checklists, audits, and incident response.

IPE shifts the mindset from reacting to failures to controlling causes before

problems occur. Every process includes

built-in risk assessment through defined Key Input, Process, and Output

Variables (KIVs, KPVs, KOVs). Variation is treated as an early warning

signal—data becomes the language of risk. Continuous monitoring replaces

periodic reviews, turning risk control into part of daily management. This integration ensures that risk prevention

is not a separate department function—it’s how the entire business operates.

2. Building Organizational

Resilience

Resilience in IPE means the

ability to continue achieving purpose under changing conditions. Processes are

designed with clarity, redundancy, and flexibility so that disruption in one

area doesn’t collapse the system. Cross-functional

process ownership creates agility—teams can quickly reassign work and

reconfigure resources. Data integration

across ERP, PLM, MES, and CRM systems ensures leadership always knows what is

happening and why. Resilient organizations don’t bounce back—they adapt forward,

learning from variation instead of merely restoring the status quo.

3. Expanding the Definition of

Sustainability

IPE broadens sustainability beyond

environmental metrics to include operational, economic, and social durability. Operational Sustainability: Processes run

predictably, minimizing waste and downtime.

Economic Sustainability: Profitability is protected through consistency,

quality, and intelligent resource use. Social

Sustainability: Employees are empowered and informed; the system supports

safety, engagement, and continuous learning.

IPE makes sustainability measurable: a controlled, capable process is

inherently sustainable because it prevents rework, reduces waste, and builds

trust across the supply chain.

4. Leadership’s Role in

Sustaining Resilience

Leaders are accountable for

creating systems that anticipate and absorb change. They model transparency, learning, and

accountability. They link risk data

directly to performance dashboards, ensuring real-time visibility into threats

and recovery progress. Leadership communication and behavior become risk

controls themselves—reinforcing confidence and clarity during uncertainty.

5. IPE as the Framework for

Sustainable Excellence

By embedding risk, resilience, and

sustainability into every process, IPE converts uncertainty into capability. Risk

identification becomes proactive. Resilience becomes structural. Sustainability

becomes measurable and repeatable. The organization evolves from protecting

against failure to engineering success that endures.

Summary Insight

In IPE, resilience and

sustainability are not goals—they are outcomes of well-managed processes. When

processes are defined, measured, and improved through integrated data and

leadership accountability, the enterprise becomes inherently stable, adaptive,

and future-ready.

The Principles of Integrated Process Excellence (IPE)

The Principles of Integrated Process Excellence (IPE)

Integrated Process Excellence (IPE) is built on the belief that sustainable success comes from managing the processes that create results, not just reacting to the results themselves. This chapter establishes the philosophical and practical foundation for IPE, defining how organizations must think, act, and lead to achieve durable excellence.

Watch the video to learn more

https://www.linkedin.com/pulse/principles-integrated-process-excellence-ipe-john-m-cachat-lsdve

1. Process Orientation vs.

Functional Silos

Traditional management structures

organize around departments — engineering, purchasing, manufacturing, sales —

each with its own goals and data. IPE replaces this siloed model with process

orientation: managing work as an interconnected flow from supplier to

customer.

- Every process has inputs, transformation steps,

and outputs that affect downstream performance.

- The focus shifts from who owns the task to how

value flows across the organization.

- Leaders learn to see the “white space” between functions — where most inefficiencies, handoff delays, and misunderstandings occur.

2. Integration of People,

Processes, and Technology

IPE integrates the human,

procedural, and digital systems that define modern work.

- People provide insight, creativity, and

accountability.

- Processes define consistency, control, and

predictability.

- Technology connects and automates workflows,

ensuring data integrity and real-time visibility.

The power of IPE emerges when these three elements operate as one integrated system rather than separate improvement efforts or software modules.

3. Customer-Driven Value

Creation

The ultimate measure of any

process is its ability to deliver value as defined by the customer.

- IPE requires that every process start with clear

understanding of customer requirements.

- Metrics, controls, and improvement goals all trace

back to what customers actually value — quality, delivery, cost, and

innovation.

- Internal processes that don’t contribute to external

value are redesigned or eliminated.

4. Continuous Improvement and

Problem Solving

IPE institutionalizes continuous

improvement as a built-in management process, not a special event.

- Every process must be measured, controlled, and

improved through feedback and learning.

- Teams use data to identify causes of variation, apply

countermeasures, and verify effectiveness.

- Instead of reacting to failures, IPE emphasizes success planning — defining what must go right to assure performance before problems occur.

5. Leadership Accountability

Leadership in IPE is defined by building

systems that sustain results, not just demanding them.

- Leaders are accountable for ensuring that processes

are defined, measured, and improved.

- They create an environment where teams can succeed

without relying on heroics or luck.

- Leadership behavior — communication, recognition,

problem-solving — becomes part of the system of excellence.

Summary Insight

The principles of IPE redefine

excellence as integration. When people, processes, and technology

operate as one continuous system guided by customer value and led by

accountable leadership, improvement becomes self-sustaining. IPE is the bridge

from traditional management — which measures outputs — to intelligent

management — which controls the causes that create them.